Baking tins and trays

With the objective of providing our industrial bakery customers with a comprehensive service, we offer – together with the entire range of products with Testrong® non-stick coatings – the design and manufacture of baking tins and trays adapted to production lines, in addition to repairs and maintenance at our specialized shop for used tins and trays. At PRAIMER, we offer the best customised option for rolls, toasted bread, whole grain bread, gluten-free bread, loaf bread, hamburger and hot dog buns, croissants, muffins and all types of sweet and savoury breads, toasts, baguettes and frozen and pre-frozen bread. Every customer is different and each production process has its specific characteristics, which is why we listen and analyse needs, consequently offering the best solution adapted to each project.

Services we offer

BAKEWARE MANUFACTURING

We have specific knowledge of the sector that allows us to optimise production, thereby considering the major importance of baking tins and trays on production lines. In an effort to provide bakers with a comprehensive service, at PRAIMER we analyse and focus our efforts on the elements that are the most susceptible to damage due to line automation, thereby extending the useful life of tins and achieving greater performance.

Direct collaboration with the best tin and tray manufacturers allows us to offer high-quality products that adapt to the specific requirements of each customer, at competitive prices. Baking tins and trays are supplied to customers after receiving the prior application of the Testrong® non-stick coating that is suited to each specific item and the end use of the product.

Tins and tin lids

To find the optimal solution that allows customers to efficiently produce their products, we work together with them. Brioche, loaf bread, toasted bread, plum cake, round bread, crustless bread and rustic bread are products that have different characteristics. To achieve the optimal final product, we analyse all the elements that can have an impact: distances, material (aluminized steel, profiles of steel or aluminized steel, etc.), bossing of the metal, ventilation orifices, reinforcements, protective strips and their position, forming, corrugation, etc.

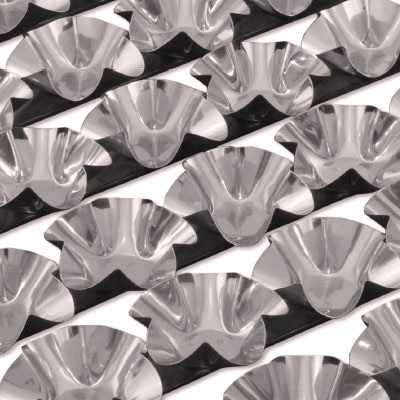

Pastry tins

We only work with high-quality and high-strength materials such as forming plates of stainless or aluminized steel with strong rear reinforcements to offer customised trays that ensure optimal performance and easy cleaning. Thanks to the high performance features, an end product is obtained through a highly efficient process. We manufacture trays for croissants, brioche, muffins, rolls, sweet rolls, cupcakes, pastas, etc.

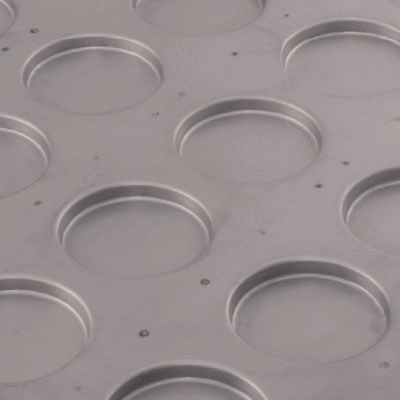

Roll trays

We offer customisable trays, with the measurements and shapes required by customers for producing their products, such as hamburger and hot dog buns, bagels or rolls, among many others. Trays are dimpled according to the characteristics of each product. Our trays are designed to guarantee optimal performance and duration, and therefore reinforcement and protection elements are added according to the production characteristics.

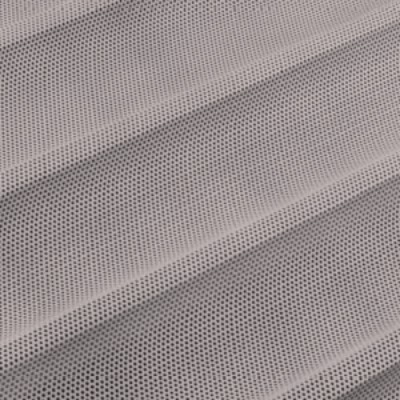

Baguette trays

During the production process, baguettes reach high temperatures, and there are abrupt changes between hot and cold, thereby accelerating the wear of trays. At PRAIMER, trays for baguettes and pre-frozen and frozen products are designed with reinforcements, thereby creating stronger trays and increasing their useful life.

MAINTENANCE & REFURBISHMENT OF BAKEWARE

The coatings of tins and trays become worn due to use. This wear process is normal, but that doesn’t mean that these parts have to be replaced with new ones. At PRAIMER we have a workshop that specialises in the recovery, repair and maintenance of worn tins and trays that still have many life cycles to offer.

The process of recovering and cleaning these tins takes place using the most advanced techniques, therefore applying Testrong non-stick coatings and obtaining practically new parts. These tins can thus be amortised over an extended period of time. This process can be repeated, depending on the characteristics of each part.

i-TRACK SYSTEM FOR BAKEWARE

We have a tracking system (Data Matrix, QR) for customers who need comprehensive tracking of their stock of tins and trays. We can monitor the useful life of their tins and trays to learn how a coating is performing at all times, thus optimising its properties. This tracking service can adapt to the customer’s needs by offering anywhere from a basic service based on the number of life cycles to a service that provides data online.