Baking industry coatings

We are backed by 20 years of experience in applying coatings, and after joining the Coatresa Group in 2008, we gained professionalism and knowledge of the European market, thereby allowing us to apply this knowledge to the bakery sector in Brazil. Through the R&D Department, we analyse and study the best products so that we can apply the best solutions and advise bakers, thereby optimising production. We use Testrong coatings, created specifically for the bakery sector to benefit bakers in their production lines, while constantly adapting to changing needs:

- Modifications to the dough.

- Changes to the formulation.

- Changes to the production process:

- Line speed.

- Baking temperatures.

Application of the Testrong® technology

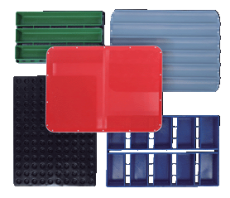

LOAF BREAD

The dough of loaf bread includes many types of bread: white, whole grain, with seeds, crustless, etc. After analysing the characteristics of each product, PRAIMER chooses the Testrong® coating that adapts the best to the specific characteristics of each type for optimal production.

SAVOURY PASTRY PRODUCTS

There are several kinds of savoury pastry products, and each one has unique characteristics. With the various Testrong® non-stick coating systems, we adapt to all products: hamburger buns, hot dog buns, rolls with seeds, rolls with special flavours, etc.

FROZEN BREAD

The high temperatures and abrupt hot-cold changes endured by trays in the production process for baguettes, frozen products, pre-frozen products or pre-baked bread mean that high-performance coatings are required for preparing a quality end product.

TOASTED BREAD

Coatings for toasted bread tins must be able to withstand the production process, which includes high temperatures and abrasion. Apart from toasted bread, various products such as croutons, bread sticks and whole grain bread with seeds each have their own characteristics, for which we choose the best Testrong coating.

PASTRIES

The high sugar content of pastries means that the production process requires a high-performance coating. With our bakery coatings, products such as Spanish brioche, croissants or puff pastries benefit from the high non-stick properties.

CAKES

With a wide range of Testrong coatings, we provide service for the demands of the cakes sector and cover the various needs of the characteristics of these products. Just like pastries, the liquid doughs of sponge cakes, drunk cakes or cupcakes require a high-performance coating.

All our Testrong® coating systems have been approved for food contact in accordance with national and international regulations, as well as certificates of migration by an independent German laboratory.

Testrong® is a range of non-stick coatings designed to satisfy the needs of the bakery sector. Designed based on fluoropolymers (PTFE, PFA, MFA, FEP, etc.) and silicones, they are the result of an in-depth analysis and the work of combining and applying the best products in the market. They provide not only high-quality coating properties but also high performance, consequently reducing costs on the production lines of industrial bakeries. The philosophy of the Coatresa Group is constant evolution and research, and thanks to its collaboration with the main suppliers of raw materials in the world, the Testrong systems are constantly evolving, thereby adapting and always covering the needs of bakers.

Our wide range of Testrong® coatings eliminates the use of oils or release agents on production lines.